ACCU

18/12/2025

Using Accu in past projects

Accu products have been used across nearly all sub-teams and projects within Project Sunride. Below are a few examples of how Accu components have contributed to the success of our projects:

Experimental – Ariel

Accu hardware was used throughout Ariel contributing to a securely assembled airframe capable of withstanding the forces during launches. A range of products – heated inserts, countersunk screws, nuts, threaded bars and eye nuts – were integrated across the rocket. Eye nuts (specifically M8) were especially important in the recovery systems as they provided reliable attachment points between the parachutes and bulkheads in the nose cone, sustainer and booster sections. Accu screws and inserts were also used in the build and integration of our ‘parachute cannon’ where the hardware successfully tolerated the ejection charge pressures and dynamic loads.

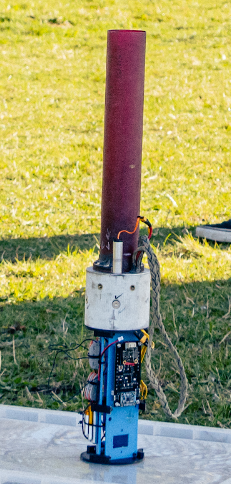

Karman – KC

Accu products played a crucial role in the sustainer avionics bay of Karman Charlie (KC). The team used M10 threaded rod along with a series of Accu nuts to mount and secure the avionics boards. This assembly provided a reliable tension structure through the upper sustainer, ensuring all internal systems remained supported throughout testing and the final launch. The team used Accu’s nylon shear pins to hold the rocket sections together until the ejection charges fired. These pins acted as a critical safety feature by preventing premature separation, and Accu’s components performed this role reliably. Accu hardware has consistently proven its reliability for our high-power two-stage rockets and we look forward to continuing to use their products in future projects.

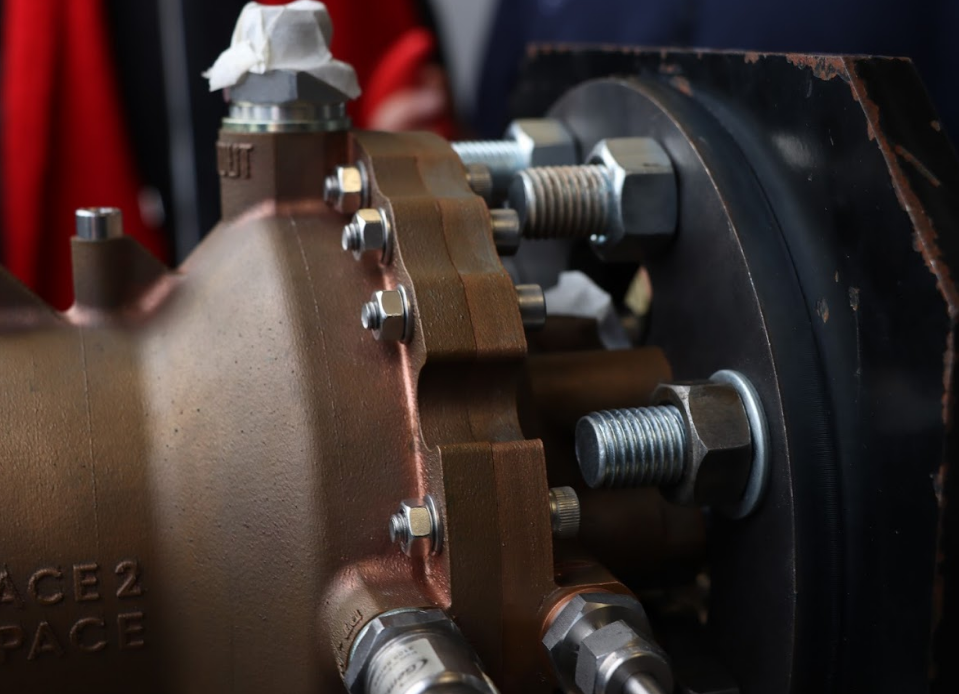

Sunfire Feed – Black Adder

Accu products were used throughout Black Adder, one of the rockets in this series to make a key step towards launching the first student liquid rocket from UK soil. The team particularly relied on Accu’s M8 heat bolts within the tank assembly and thrust structure. Both sections face extreme operating conditions – the tank contains high pressure oxidiser and fuel while the thrust structure accommodates combustion and thrust generation. Hardware in these areas must withstand the high pressures, elevated temperatures and significant launch loads as well as prevent leakage at joints. The strength and reliability of Accu’s bolts allowed these systems to remain secure and structurally sound throughout the successful testing.

Sunfire Engine – Sunfire V

Sunfire Engine sub-team uses a range of Accu products throughout its build and testing. Their bolts are used in the injector and combustion chamber to maintain structural integrity under the high pressures and temperatures during testing and full-stack. These bolts also prevent leaks, ensuring safety and consistent and predictable engine performance. Additionally, M10 bolts are used to secure the engine to the test stands. The strength and reliability of these Accu bolts allow the engine to be held safely against the forces generated during firing and effectively handle the engine vibrations which will reduce the risk of fatigue failure. Accu bolts have proven to be highly reliable and provide maximum safety, and we look forward to continuing to use them through their operating life.