Sunfire V

About

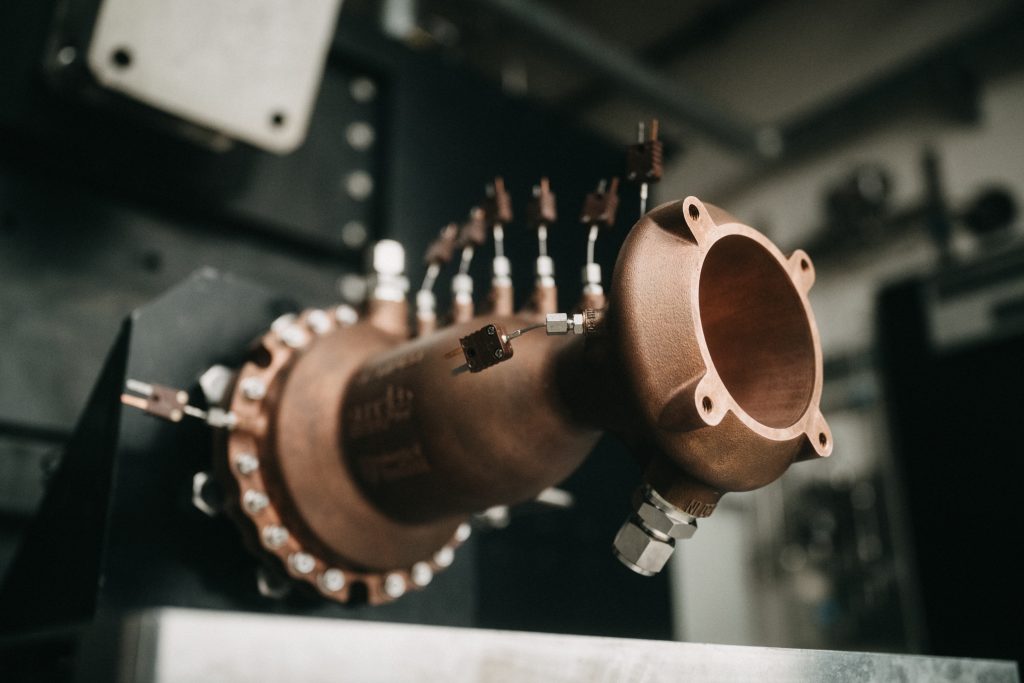

Sunfire V, also known as Rusty, was Project Sunride’s entry to Race 2 Space 2025. SF-V burned Liquid Oxygen and IPA in an additively manufactured copper chamber with integral water cooling. At the competition in June 2025, SF-V produced 6.1 kN of thrust and achieved a UK record efficiency of 241s of ISP, which won Sunride the “Best LOx Biprop” award.

The engine was additively manufactured from CuCrZr by Aconity3D and cooled using high-pressure water through its integral cooling channels. This enabled us to push it to higher operating temperatures and achieve outstanding performance metrics, such as obtaining an specific impulse that was 50% higher than our Sunfire III engine!

Race 2 Space

Sunfire V was designed for a test-bed and to enter Race 2 Space 2025, a unique competition that allows students from around the world to connect with industry mentors and test their rocket engine desgins.

This year marked the first time the Sunfire Engine team hot-fired a triplet injector, designed a CuCrZr engine, and tested with cryogenic propellant.

On the 25th of June, Sunride successfully hotfired Sunfire V, kicking off the first day of the Race 2 Space 2025 Student Propulsion Competition.

Test Results:

– Test 1: 4.3 kN burn for 5 seconds,

– Test 2: 5.2 kN burn for 6.5 seconds,

– Test 3: 6.1 kN burn for 10 seconds.

We’re excited to see what the rest of the Race 2 Space competition brings, and we look forward to sharing our data with the broader collegiate rocketry community! Thank you to the Race 2 Space team and Dr Alistair John for the testing opportunities this year.

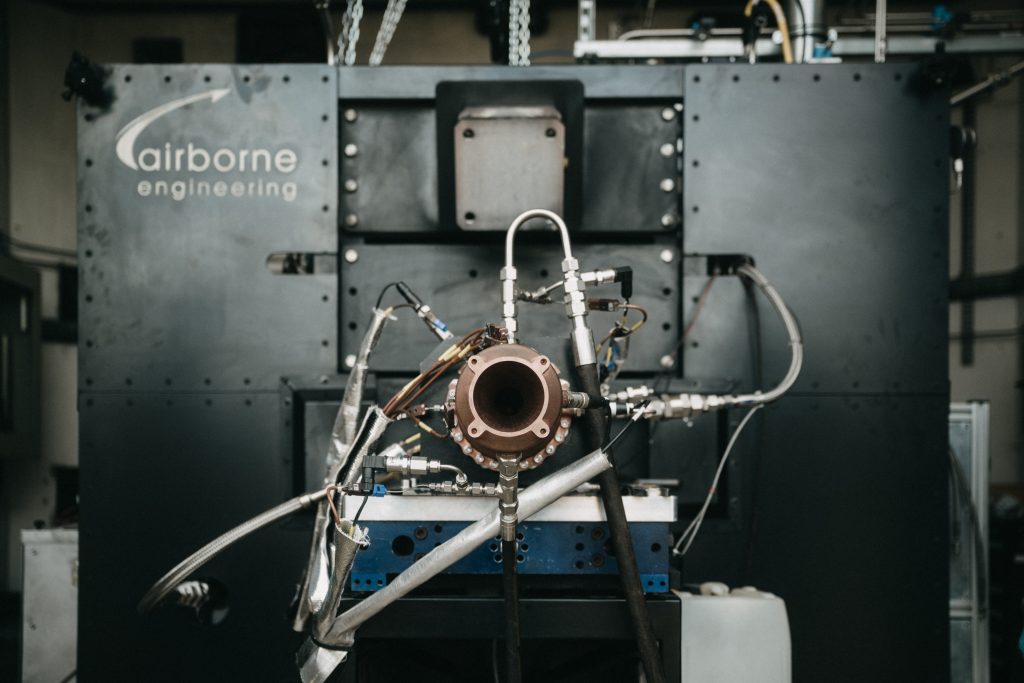

ACONITY3D & AIRBORNE ENGINEERING

Thank you to Aconity3D for 3D printing Sunfire V, who allowed us to push the limits of what a student team can achieve! For the Race 2 Space 2025 competition, Aconity3D supported so many teams in particupating by manufacturing numerous rocket engines.

Thank you also to Airborne Engineering Ltd for the use of their test stand and the invaluable expertise they provided on the day.